The roofing industry in the United States has witnessed significant advancement over the past three decades. The widespread use of advanced plastics such as Thermoplastic Olefin (TPO) in the construction industry has facilitated complex or demanding projects for which more conventional materials like asphalt shingles cannot be used. With this article, we will introduce you to the advantages and disadvantages of TPO roofing, the most common applications of this technology and suggest some alternatives for it.

Table of Contents

What is TPO Roofing?

TPO, or thermoplastic olefin, is a generic term for a very broad group of plastic blends that are often used in the construction and automotive industries. Using polyethylene or polypropylene, TPO is malleable when heated, the use of fiberglass gives consistency, while the use of EPR or other elastomers ensures that your roofing will not be fragile.

How are TPO Roofs Installed?

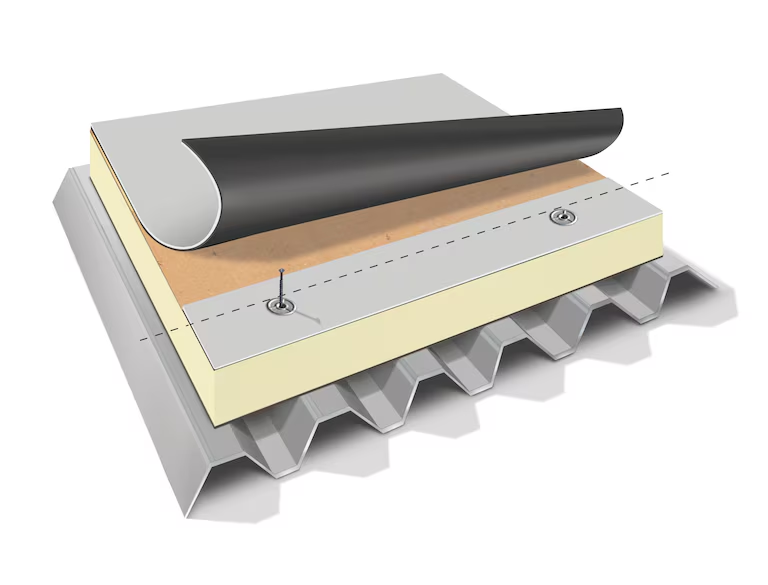

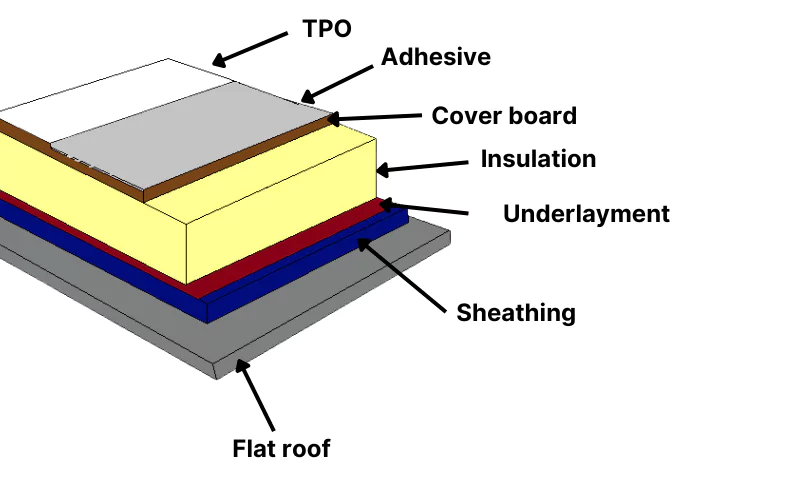

TPO membranes are, as a rule, adhered to flat roofs or those with very little slope. Sold in rolls, the membrane is deceptively similar to underlayment, but has a different structure and function. Roofing membranes made of thermoplastic polyolefin are usually glued to flat surfaces and additionally welded at the edges for maximum airtightness. Thanks to their high fusibility, it only takes about 270 degrees Celsius (520 degrees fahrenheit) to solidly weld the layers and protect them for many years.

In the vast majority of cases, TPO membranes are brightly colored, such as white. This is to achieve the best possible reflectivity, which translates into lower costs for air-conditioning the attic and upper parts of the building.

How TPO Roofing Works?

When thinking about TPO roofing, it is useful to imagine stretch film that you stretch over food – the membrane is supposed to form a gently stretched, waterproof surface that does not allow air to pass through. Sheets can be installed with mechanical fasteners, but this method is not popular due to the markedly increased risk of leaks.

Sometimes it also happens that TPO membranes are backfilled with a layer of gravel, which further protects the entire structure from wind pressure.

When is it Worth Choosing TPO Roofing? Pros and Cons

It is worth noting that although TPO roofs are a relatively modern solution offering very good performance, as is usually the case, they also have drawbacks. Let’s analyze all the arguments for and against this technology:

Initial Cost

One of the most significant advantages of TPO roofs is their cost-effectiveness. Compared to other single-ply membranes like PVS, the cost of purchasing the material as well as the installation service itself is noticeably lower, which is very important for commercial roofing projects. Estimates of the cost of installing 1 sqft of PVC roof range from $12 to $15, while TPO costs about $11-$14 per sqft. Even for a roof on a family home, a thermoplastic olefin membrane will be about $4,000 cheaper. The differences get really significant when you are looking for rooftop material for an office building or warehouse. Then, PVC may turn out to be more expensive by, for example, $20,000.

Energy Efficiency

Thanks to their high tightness, complex structure and customary white color, TPO membranes are surprisingly good insulators – convection and conduction effects are reduced to a minimum, and on top of that, white surfaces heat up much less than, for example, black or brown ones. The R-value of most single-ply membranes ranges from 0.24 to 0.33.

Energy efficiency translates primarily into lower energy costs for air conditioning. This is key especially in warmer regions, but even if you have to heat your home for a significant part of the year, a well-insulated roof is desirable because indoor temperatures are more stable.

Durability and Longevity

TPO membranes are adapted to function in a wide variety of conditions – they perform quite well in both cool and warm regions, although it is worth reckoning with some vulnerability of this material to high temperatures.

Lifespan of TPO roofs, which is usually estimated at 25 years, is significantly reduced when the surface is exposed to direct UV radiation.

Ease of Installation

Because of the material’s light weight, its sale in roll form and its ability to be adhered with a wide variety of adhesives, TPO single-ply roofing membranes are very easy to install, and the whole process is quick. The chemical properties of the most popular materials also mean that they can be installed even during severe cold weather, which is very important – roofing contractors’ services are much cheaper in winter than in summer due to lower demand.

Environmental Impact

TPO is considered a fairly environmentally friendly roofing technology – used single-ply can be recycled in significant part, and no toxic chemicals are released during its proper use. An additional advantage of thermoplastic olefin is its relatively good insulation performance, so if your roof is further insulated with efficient materials, your heating and air conditioning bills will be low.

Variability in Quality

“TPO” is a very broad term, much like ‘asphalt shingles’ or ‘fiber cement siding‘. While the chemical compounds that make up each type of thermoplastic have similar parameters, the differences between products from different brands are very pronounced. Companies such as GAF and Carlisle, as a rule, are practically always trustworthy, but if you decide to choose less popular, budget solutions, you have to expect a greater risk of the rapid appearance of leaks or discoloration. This is especially evident with membranes from years ago.

Installation Sensitivity

The process of installing single-ply roofing membranes is quite easy in principle, but as a roofing contractor with more than 20 years of experience, we have already seen many times that TPO is not always installed correctly.

By far the most common mistake is the inadequate use of welding machines – too long exposure of the thermoplastic to high temperatures can lead to degradation of its structure, while too low temperatures will not ensure proper tightness of the joints.

Poor Repairability

The vast majority of single-ply roofing membranes are not designed to be easily repaired, and TPO is no exception in this regard. Due to its very low thickness, which is typically 0.045“ to 0.09”, and its rather high stretch, it is very difficult to patch any leaks and in many cases, replacement rather than repair is the more recommended solution.

Comparison with Other Roofing Materials

TPO vs. EPDM

EPDM is a synthetic rubber membranes that has gained popularity in the roofing industry due to its combination of high durability and above-average flexibility. It is worth noting, however, that EPDM is a plastic dedicated to operation primarily in cold climate zones, not least because of its black or dark gray color. TPO creates a much more reflective surface, making it better suited for temperate and warm climates.

TPO vs. PVC

PVC roofing membranes are more similar to those made from thermoplastic olefins. However, let’s point out that polyvinyl chloride is more resistant to many reactive chemicals, including alcohols, common solvents and acids. This is an important parameter, but it counts more when choosing a flooring material rather than a rooftop cover. Roofs are relatively rarely exposed to corrosive chemicals, especially in residential applications.

Note, however, that PVC membranes are up to 35% more expensive than comparable products made of TPO. PVC is also less environmentally friendly due to its chlorine content, which is biocidal.

TPO vs. Modified Bitumen

From a technical point of view, modified bitumen roofing is quite similar asphalt shingles – this material is also made from asphalt, but polymers are also used in its production, which give it a structure that allows it to achieve higher airtightness.

However, in the article title What is underlayment?, we wrote about the main disadvantage of bitumen membranes – they are extremely heavy, which forces the roofing contractor to use additional reinforcements for the truss structure, and also increases installation costs due to the need to involve more people in transporting rolls of bitumen membranes.

Compared to asphalt roofing, TPO exhibits lower weight, an easier installation process and better reflectivity due to its light color. It is also a much newer technology.

Factors to Consider Before Choosing TPO Roofing

The Climate Where You Live in

TPO roofing works well in a wide variety of climates as well as in areas where temperature fluctuations are high, but as a general rule, a membrane made of thermoplastic olefins will require a very thick insulation layer, which will raise the cost of roof replacement. We should also add that the white color will not be helpful when the number of hours of sunlight per year is low and you need to heat your home.

With cheaper membranes, there may also be a problem with effective welding – temperatures that are too low can accelerate the cooling of the material too much, damaging its internal structure. In the simplest terms, welding thermoplastic olefins in the cold can lead to the breaking of bonds between the molecules that make up the polymer as a whole.

Building Type and Usage

TPO can be used on both commercial and residential roofs, it is not a major problem. Note, however, that single-ply membranes are unlikely to be installed on pitched roofs.

If you’re looking for a roofing membrane for a building located in an industrial area, it’s also worth considering another material, such as asphalt or even PVC. These are more resistant to contamination, and often have a color that does not show pollution.

Budget Constraints

Admittedly, TPO roofing convinces with its relatively low initial cost, but it is worth being aware that savings always reflect on some parameters. In the case of thermoplastic, the long-term durability of the plastic in areas that are exposed to intense UV radiation can be problematic.

Homeowners also very rarely pay attention to the possibility of later repairing their roofs, which can carry very serious financial consequences just a few years after installation. After all, note that damaged slate tile or cedar shake can be replaced one at a time. With single-ply membranes, this is not possible.

Availability of Experienced Contractors

We are one of Glenview’s few TPO roofing contractors Glenview. Many companies are reluctant to undertake the installation of this type of roof, which can make the cost of the service high. An inexperienced roofer can also damage the membrane, which you will only find out after a while, usually during very heavy rainfall.

Summary

TPO roofing can be a very interesting alternative to metal panels or modified bitumen. Single-ply membranes entice with their attractive price, decent insulating properties and aesthetics, but it is worth remembering that for their installation you should hire an experienced roofing contractor who will not make any mistakes. If you live in Chicagoland and plan to install a TPO roof, A.B. Edward would be the best possible choice.