Best Home Exterior Services Contractor in Chicago North Shore Area

A.B. Edward is a family-owned company that offers roofing, siding, gutter, carpentry and masonry services that will delight you with quality. We operate i.e. in Winnetka, Glenview, Chicago, Northbrook, Evanston and Highland Park.

Rich Offer Of Exterior Services

A.B. Edward’s offer includes all the services necessary for a comprehensive exterior remodeling. Thanks to the cooperation of more than 40 specialists employed by our company, we are able to undertake the repair and replacement of the roof, siding and gutters, as well as the terrace, patio and driveway. We will also take care of the installation of garage doors and windows in your home. With us, any home exterior can get a new, unprecedented charm.

Top Quality For A Reasonable Price

Top Quality For A Reasonable Price

As a renowned roofing contractor from Wheeling, we have already served thousands of clients from all over the North Shore. The reviews don’t lie – the projects we complete are refined in every way.

Providing a comprehensive package of exterior services, including roofing, siding, masonry and stone work, we will take care of your home like no other company and solve any problem related to finishing your property. Operating continuously since 2003, we have completed more than 36,000 projects – both large and small. We use the best materials and partner with many brands such as GAF, DaVinci Roofscapes, CUPA and James Hardie.

847-827-1605

Team Of Qualified Exterior Specialists

Team Of Qualified Exterior Specialists

As a reputable Exterior Contractor providing services in Wheeling, Winnetka, Highland Park, Chicago, Northbrook, Evanston, Deerfield and surrounding areas, we employ top-notch professionals. Our roofing, siding, carpentry and masonry teams consist of people with many years of experience and all the necessary licenses and qualifications. We regularly participate in training courses organized by popular brands, making us a certified installer. Thanks to our diligence and constant motivation to develop, your home exterior is in the best possible hands.

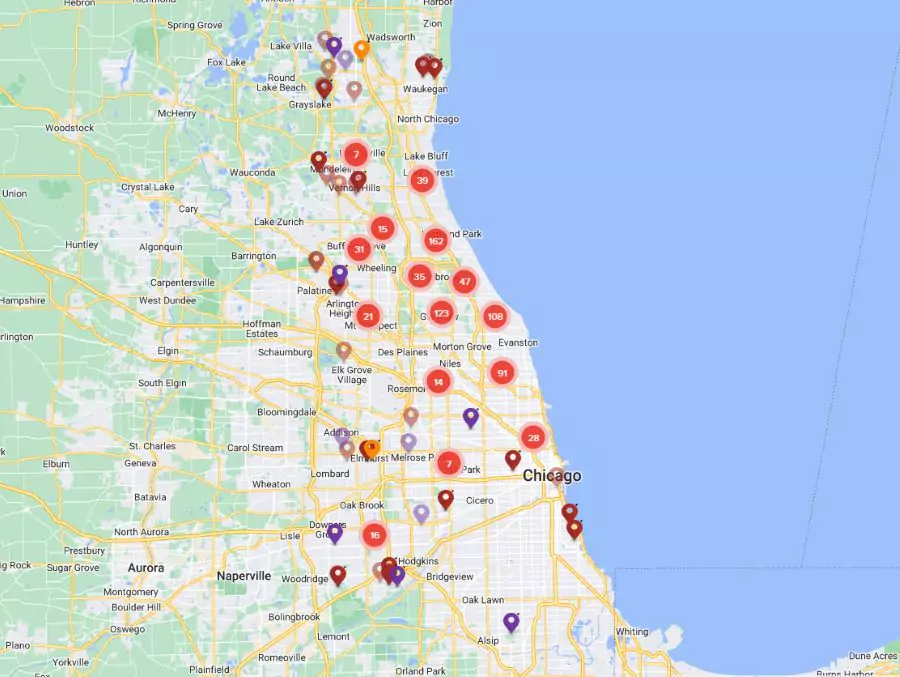

Locations

Locations

We serve clients throughout the Chicagoland area. More than 11,000 families reside in Glenview, Chicago, Northbrook, Evanston, Highland Park, Deerfield, Winnetka, Glencoe, Lake Forest, Park Ridge, Wheeling, Barrington, Northfield, Buffalo Grove, Lincolnshire, Inverness, Arlington Heights, Mount Prospect, Des Plaines, Palatine, Hinsdale, Vernon Hills and Riwerwoods. Our company’s cars, wrapped in the distinctive red and white film, inspire confidence and associate locals with quality, express delivery times and stunning final results.

847-827-1605

Innovation And Commitment To Tradition

Innovation And Commitment To Tradition

We are proud of the 20 years of work we have dedicated to building ties within the company as well as with the local community. Since its inception, A.B. Edward has handled hundreds of home exteriors in multiple locations throughout Chicagoland. More than 1,600 clients in Glenview, 600 in Northbrook, 500 in Chicago, and 450 in Winnetka can attest to our commitment to a variety of projects, whether they are classic American style or extremely modern residences that architecturally incorporate European and Asian trends. Our brand is a synonym for quality.

FAQ

A.B. Edward is engaged in providing exterior services such as roof repair, gutter replacement and masonry, carpentry. We also offer installation and maintenance of doors, windows, garage doors and skylights.

In addition to roof, window and gutter repairs and replacements, we also offer periodic maintenance and cleaning.

A.B. Edward provides exterior services on Chicago’s North Shore and in Chicago itself. We most often serve clients in Glenview, Chicago, Northbrook, Evanston, Highland Park, Winnetka, Vernon Hills, and Wheeling.

Our company has been on the market since 2003. During this time, we have completed more than 11,000 projects, working with more than 7,000 clients. From the very beginning, we have been associated with roofing and guttering, and our offer was very quickly expanded by siding, masonry, carpentry, and decking services.

Although our specialty is the repair and maintenance of residential properties, we also have many commercial and sacred projects in our portfolio. We have renovated garages, warehouses, stores, churches, synagogues and office buildings.

If you are a business client, contact our sales department right away – we will prepare an individual offer for you at preferential terms.

We pride ourselves on providing each of our customers with above-average quality service, from pre-purchase service to a warranty for the work we have completed.

Regardless of the complexity of the project or the amount you pay us, the service we provide will be performed to the highest standards and your home will be an even more wonderful place.

When you choose A.B. Edward, you get quality service, top-notch materials and the confidence that a particular defect will not return for many years.

Let’s face it – nothing related to real estate is cheap. Prices are driven primarily by the amount of materials and labor that must be spent to complete the job. Of course, some construction solutions allow you to save some money, but exterior services as a rule put a strain on the household budget.

Are our services expensive? We don’t like to compete on terms of price, but our clients find that we price our work very reasonably. We can also guarantee you that you will remember the quality much longer than the price!

Like any legitimate exterior services company in the Chicago area, A.B. Edward has all the necessary licenses and insurance. We take great care to meet all, even the most stringent formal requirements, so you can rest assured – you are completely safe in terms of formalities.

We pride ourselves on an exceptionally high level of customer service – hundreds of positive reviews testify to this. We know that other companies are also praised, but we don’t know anyone who pays as much attention to detail. After each job, we perform a very thorough cleaning of the area around your home, so you can be sure you won’t be standing on a nail or other debris. We also care about your comfort – we work in such a way that we don’t disturb your late afternoon. We try to adapt to you and ensure that you are properly attended to.